Toilet Roll Making Machine

Price 650000.0 INR/ Unit

MOQ : 1 Unit

Toilet Roll Making Machine Specification

- Grade

- Industrial

- Type

- Other

- Material

- Metal

- Capacity

- 2-4 tons/day

- Computerized

- Yes

- Control System

- PLC automatic control

- Cutting Speed

- 120-180 cuts/min

- Cutting Size

- 90-200 mm

- Cutting Thickness

- 0.8-2 mm

- Voltage

- 380V/50HZ

- Power

- 4.5 kW

- Weight (kg)

- 2200 kg

- Dimension (L*W*H)

- 6500 X 2500 X 1750 Meter (m)

- Color

- Silver

- Max Rewinding Diameter

- 120 mm

- Core Diameter Range

- 25-50 mm

- Cutting Method

- Automatic reciprocating cutting

- Paper GSM Range

- 14-30 GSM

- Driven Type

- Electric

- Lubrication System

- Auto-lubrication

- Unwind Stand

- 2 Ply

- Noise Level

- Less than 70 dB

- Operator Required

- 1-2 persons

- Sensor Type

- Photoelectric sensor

- Automation Grade

- Fully Automatic

- Embossing Unit

- Steel to Rubber

- Parent Roll Diameter

- Max 1200 mm

- Air Pressure Required

- 0.6 MPa

Toilet Roll Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Week

- Delivery Time

- 2 Months

About Toilet Roll Making Machine

Specification

| Dimension | 6500 X 2500 X1750 MM |

| Automation Grade | Automatic |

| Capacity | 80-280 M/MIN |

| Machine Type | AUTOMATIC |

| Voltage | 0.6 MPA |

| Napkin Type | ROLLER |

| Driven Type | Panal |

| Brand/Make | IMPORTED |

Efficient Fully Automatic Operation

This machine is engineered for autonomous performance, featuring PLC automatic control and computerized systems that enable quick and precise adjustments. Operators can manage the unit seamlessly, requiring only 1-2 persons for full operation, minimizing labor costs and reducing human error. The use of photoelectric sensors ensures reliability in tracking and cutting, optimizing both safety and productivity.

Superior Cutting and Embossing Capabilities

The unit utilizes automatic reciprocating cutting and steel-to-rubber embossing, resulting in uniformly textured toilet rolls. With a rapid cutting speed of up to 180 cuts per minute, it can process a wide range of paper thicknesses (0.8-2 mm) and sizes (90-200 mm), making it adaptable for different market needs. Auto-lubrication sustains machine performance for continuous operation.

FAQs of Toilet Roll Making Machine:

Q: How does the toilet roll making machine ensure consistent quality in every roll?

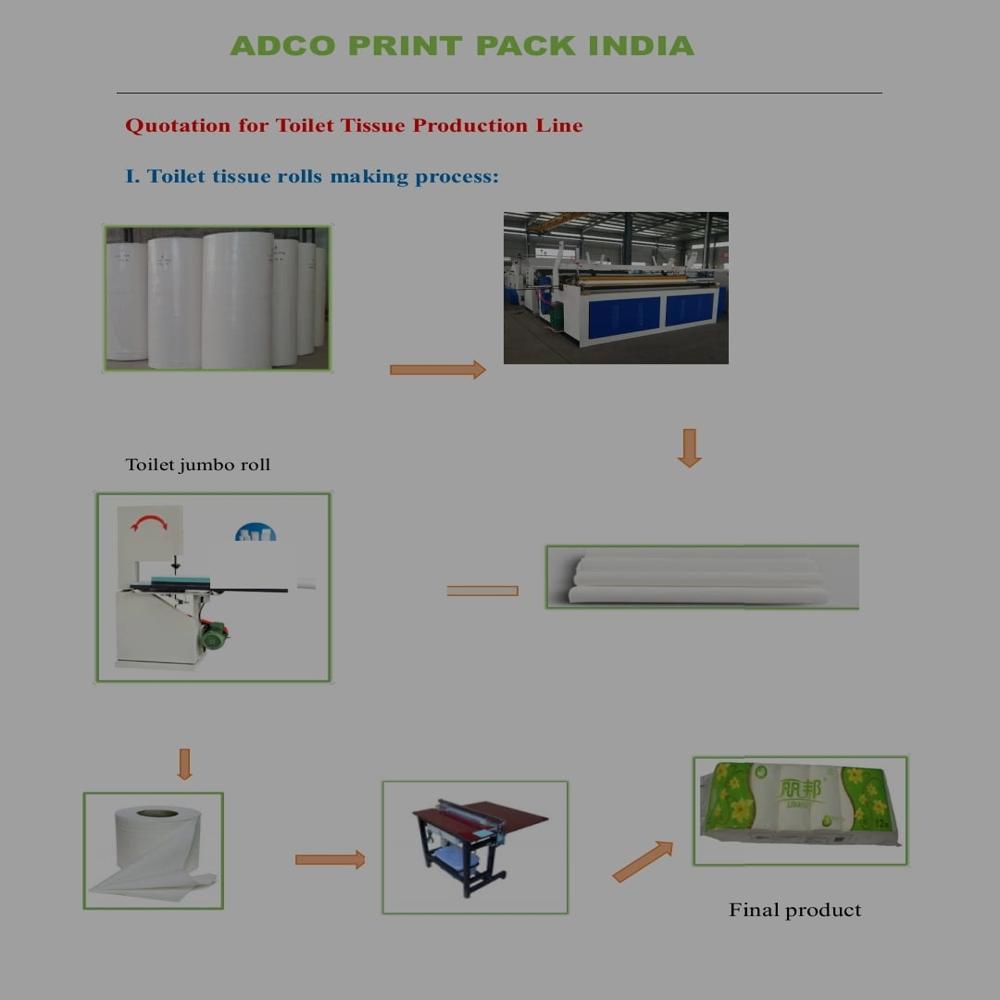

A: The machine uses a steel-to-rubber embossing unit for uniform texture and an automatic reciprocating cutting method for precise length and thickness. The PLC control system and photoelectric sensors maintain consistent operation, resulting in high-quality toilet rolls batch after batch.Q: What are the process steps involved in producing toilet rolls using this machine?

A: The process begins with feeding the parent roll onto the 2-ply unwind stand. The machine then embosses the paper, rewinds it onto cores with diameters from 25-50 mm, and automatically cuts the rolls to specified sizes between 90-200 mm. The auto-lubrication and computerized controls ensure efficient and smooth production throughout.Q: When is this machine suitable for use in toilet roll manufacturing?

A: This machine is ideal for use in high-volume, industrial-grade toilet roll production environments where consistent quality, efficiency, and reduced labor input are crucial. It suits manufacturers, distributors, and suppliers aiming for reliable daily output of 2-4 tons.Q: Where can the toilet roll making machine be installed and operated?

A: It is suitable for installation in industrial facilities in India and can be utilized by manufacturers, exporters, importers, wholesalers, and retailers requiring large-scale toilet roll production. Its dimensions (6500 x 2500 x 1750 meters) make it appropriate for dedicated production spaces.Q: What benefits does the fully automatic control system offer to operators?

A: The PLC-based automatic control system streamlines production processes, minimizes manual supervision, and reduces operation errors. Operators benefit from simplified monitoring, enhanced safety, and the ability to efficiently manage high-speed manufacturing with just 1-2 personnel required.Q: How does the machines cutting speed impact productivity?

A: With a cutting speed of 120-180 cuts per minute, the machine boosts productivity and meets demanding market requirements. This rapid rate facilitates daily outputs of 2-4 tons, supporting the continuous supply chain for distributors and retailers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paper Cup Making Machine Category

Paper Cup Making Machine

Price 550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 12 Months

Color : Blue & Gray

Material : Mild Steel

Grade : Automatic

Paper Cup Glass Making Machine

Price 8500000 INR / Container

Minimum Order Quantity : 1 Container

Warranty : 1 YEAR

Color : BLUE or yellow

Grade : Automatic

Aluminum Foil Container Making Mould

Price 450000 INR / Container

Minimum Order Quantity : 1 Container

Warranty : 1 year warranty

Material : USE PAPER FOR RAW MATERIAL

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free