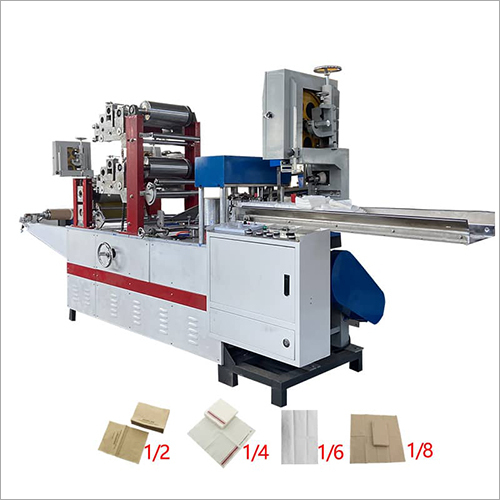

Paper Napkin Making Machine

Price 521000.0 INR/ Unit

Paper Napkin Making Machine Specification

- Lubricating System

- Automatic lubricating system

- Power Rating

- 3 HP

- Noise Level

- Below 85 dB db

- Machine Type

- Semi-Automatic Paper Napkin Machine

- Frame Type

- Heavy Duty Welded Frame

- Voltage

- 220V / 380V Volt (v)

- Cooling System

- Air cooled

- Operating Temperature

- 5C - 40C Celsius (oC)

- Frequency

- 50 Hz Hertz (HZ)

- Connectivity Options

- Manual and electrical interface

- Drive

- Chain Drive

- Model No

- PN-420SM

- Features

- Sturdy construction, Low maintenance, Easy operation

- Motor Power

- 3 HP Horsepower (HP)

- Product Type

- Paper Napkin Making Machine

- Technology

- Mechanical with semi-automatic operation

- Power Source

- Electric

- Power

- 3 HP Horsepower (HP)

- Surface Treatment

- Polished metal finish

- Weight (kg)

- Approx. 950 kg Kilograms (kg)

- Usage & Applications

- For producing paper napkins of various sizes

- Installation Service

- Available

- Folding Type

- V and N fold

- Napkin Size Range

- 200x200 mm to 400x400 mm

- Operational Training

- Included

- After Sales Support

- Provided by manufacturer

- Embossing Unit

- Integrated (optional designs)

- Roll Width

- 180 mm - 600 mm

- Number of Lines

- Single/Dual (customizable)

- Cutting System

- Rotary blade cutting

- Safety Features

- Emergency stop, safety covers

- Max Unwind Diameter

- 1200 mm

- Packaging

- Single or multiple stacks

- Raw Material Used

- Tissue Jumbo Roll

Paper Napkin Making Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Faridabad, Haryana

- Payment Terms

- Cash Advance (CA), Cheque

- Supply Ability

- 2 Units Per Week

- Delivery Time

- 1 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Paper Napkin Making Machine

Specification

|

Automation Grade |

Automatic |

|

Capacity |

400-500 PIECEPER MINUTE |

|

Napkin Type |

N FOLD M FOLD V FOLD |

|

Machine Type |

Bandsaw |

|

Packaging Type |

SEALING TYPE |

|

Brand/Make |

IMPORTED |

WE ARE THE LEADING MANUFACTURER OF PAPER CUP MAKING MACHINE AND RELATED PRODUCTS IN ENTIRE STATES - UTTAR PRADESH, HARYANA, RAJASTHAN, GUJARAT, MAHARASHTRA , PUNJAB , BIHAR , DELHI ETC.

THIS KIND OF NAPKIN FOLDING MACHINE IS MAINLY USED FOR EMBPSSING , WHICH IS CUT WELL INTO SQUARE OR RECTANGULAR NAPKIN PAPER .

IF YOU NEED BE CUSTOMIZED ACCORDING TO YOUR DETAILED REQUESTS .

Advanced Versatility for Paper Napkin Production

This machine accommodates a wide range of tissue jumbo roll sizes and delivers both V and N folds, allowing for customizable napkin dimensions to suit varying market demands. Its semi-automatic operation, PLC control, and dual production line options extend its capabilities for diverse usage scenarios.

Safety, Reliability, and Support

Operator safety is prioritized with features like emergency stop and comprehensive safety covers. Each machine includes installation service, thorough operational training, and after-sales support directly from the manufacturer, ensuring reliable operation and peace of mind.

Precision, Speed, and Low Maintenance

With a high output of up to 1200 napkins per minute, the PN-420SM maintains precise cutting and folding accuracy. The heavy-duty welded frame and automatic lubricating system contribute to its lasting durability and reduced maintenance requirements.

FAQs of Paper Napkin Making Machine:

Q: How does the PN-420SM ensure high precision during napkin cutting and folding?

A: The machine uses rotary blade cutting technology combined with accurate PLC control, resulting in consistently precise cutting and folding of napkins, even at high production speeds.Q: What is the installation process for the Paper Napkin Making Machine?

A: Installation is performed by trained technicians from the manufacturer, who set up the machine, provide operational training to staff, and ensure the system is fully functional before handover.Q: When should I perform routine maintenance on this machine?

A: Routine maintenance is minimal, owing to its automatic lubricating system. General inspections and cleaning are recommended according to the manufacturers schedule, typically after every operational cycle or as specified in the user manual.Q: Where can the machine be operated safely and efficiently?

A: The PN-420SM is designed for indoor factory environments within temperatures of 5C to 40C. Safety covers, emergency stop, and low-noise operation (below 85 dB) ensure both safety and comfort in standard industrial settings.Q: What type and size of raw material can be used for this machine?

A: It is compatible with tissue jumbo rolls, with a roll width between 180 mm and 600 mm and a maximum unwind diameter of 1200 mm, allowing manufacturers to produce a variety of napkin sizes efficiently.Q: How does the embossing unit benefit napkin production?

A: The integrated embossing unit allows optional decorative designs to be added directly to the napkins, enhancing product appeal and enabling differentiation in the market without requiring separate equipment.Q: What after-sales support and training are included with this machine?

A: Comprehensive after-sales support, operational training, and installation services are provided by the manufacturer, ensuring smooth integration and ongoing assistance throughout the machines lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Napkin Making Machine Category

Automatic Tissue Napking Making Machine

Price 521000 INR / Unit

Minimum Order Quantity : 1 Unit

Power Source : Electricity

Surface Treatment : Painted

Color : Gray

Operating Type : Automatic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS